We not only offer advanced bioprinting machines, but also provide tailor-made solutions to be your reliable partner in research.Our service process is as follows

New materials refer to structural materials with excellent properties and functional materials with special characteristics that have recently been developed or are under development. The DIW (Direct Ink Writing) 3D printing technology offers unique advantages in validating new materials, including material diversity and innovation, personalized complex structures, rapid validation, and cost reduction. These benefits make DIW technology an indispensable tool in the new material R&D process. By precisely controlling printing parameters, DIW technology achieves fine control over the rheological behavior of materials, allowing even low-viscosity slurries to be effectively printed without additives, preserving the original properties of the materials.

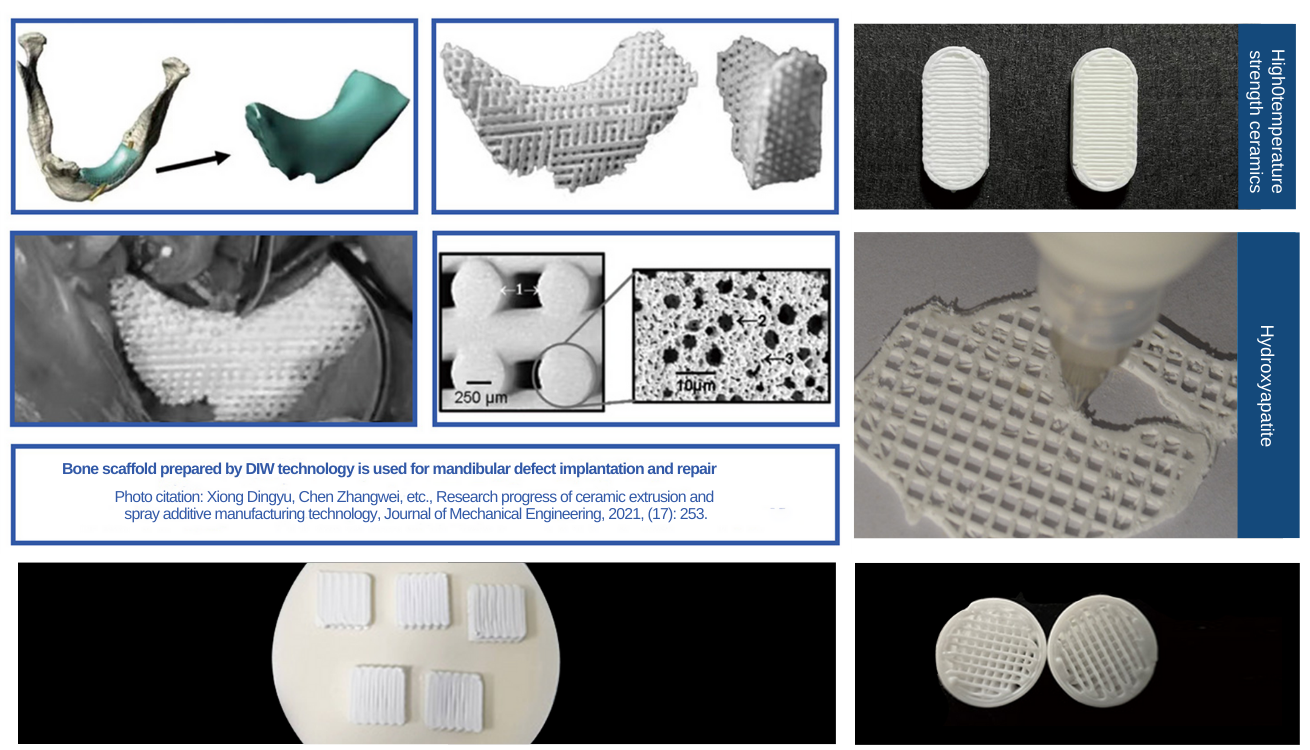

DIW 3D printing technology offers significant advantages in biomedicine, including personalized treatment, rapid manufacturing of complex structures, biocompatibility and bioactivity, and drug development and cell research. Through custom medical device fabrication, artificial organ development, cell culture, and personalized treatment via bio 3D printing, DIW technology is making important contributions to improving human health and quality of life.

3D printing is considered a transformative technology in drug formulation due to its flexibility in shaping and precise dose control. Unlike traditional methods that produce homogeneous, standardized, and single-function formulations, 3D printing allows for the spatial distribution of drugs and excipients in three dimensions. This enables the creation of heterogeneous drug delivery systems with precise control over release time, speed, location, and dosage. By accommodating drug characteristics and real-world clinical pharmacokinetics, 3D printing facilitates the customization and production of personalized and innovative formulations on demand.

DIW ink 3D printing technology offers more personalized and precise solutions in the medical aesthetics industry, enabling refined and customized beauty treatments. This enhances the level of aesthetic technology and the effectiveness of medical beauty procedures.

The process involves mixing the required special material powders, ceramic powders, and binders to create a slurry. This slurry is then printed into shape using a DIW (Direct Ink Writing) 3D printer. After printing, the model undergoes a series of post-processing steps, including debinding and high-temperature sintering, to achieve the final form. By analyzing variations in materials, composition ratios, and post-processing methods, new material formulations and functional characteristics can be developed. The DIW technology is favored by many research institutions due to its simple slurry preparation, high basic material content, streamlined process, and capability to print with multiple materials.

Adopts an Independent Dual Extruder (IDEX) structural design, a four-printhead configuration, chip redundancy design, and a reserved expansion dock design, enabling multi-modal scalability.

With a nozzle diameter of 0.1 mm, pressure accuracy of +0.2kPa, mass error accuracy of +3%, and mechanical positioning accuracy of +10um, it meets high-precision forming require-ments.

Equipped with imported pressure regula-tors, supports real-time control with pressure fluctuations ≤+2KPa. Digital pressure adjustment and clear experimental data provide detailed data validation for research.

Features a redundant design and reserved expansion dock, allowing for real-time upgrades to meet new demands discovered during experiments.

Supports various auxiliary forming functions and modules, including high-temperature and low-temperature print heads, high-temperature and low-temperature platforms, UV curing mod-ules, coaxial modules, and electrospinning. This provides diverse forming environments to meet the needs of different materials and forming con-ditions.

|

|

|

| Model Name | AutoBio(Flagship) | AutoBio(Professional) | AutoBio(Standard) |

| Build Volume | ≥300mm*200mm*100mm | ≥250mm*150mm*100mm | ≥220mm*150mm*100mm |

| Z Axis | Double Z Axis | Single Z Axis | Single Z Axis |

| Multi-Channel | Four Printheads | Double Printheads | Single Printhead |

| Calibration | Automatic Calibration | Automatic Calibration | Manual Calibration |

Air Pressure Regulation | Software/Manual Adjustment | Software/Manual Adjustment | Manual Adjustment |

| Materials | Slurry, Liquid, Suspension, Melt (Solution, Suspension, Slurry Or Melt ComposedOf Silica Gel, Hydrogel, Gelatin, Hydroxyapatite, Drug Cell suspension, Liquid, Etc.) | ||

Function Expansion | High Temperature Printing Module/Low Temperature Printing Module/High Temperature Printing Platform Low Temperature Printing Platform/Ultraviolet Curing Module/Coaxial Module | ||