Material Testing Research 3D Printer

Release date:2025-11-04 16:54:43

DIW printer Bioprinter

Release date:2025-11-04 16:54:43

DIW printer Bioprinter

Wide Material Compatibility | printing pastes can be rapidly prepared on-site.

The AutoBio Series DIW (Direct Ink Writing) 3D Printing System is designed for research and material testing applications.

It supports a wide range of printable materials, allowing researchers to quickly prepare and adjust printing slurries on site to meet specific experimental needs.

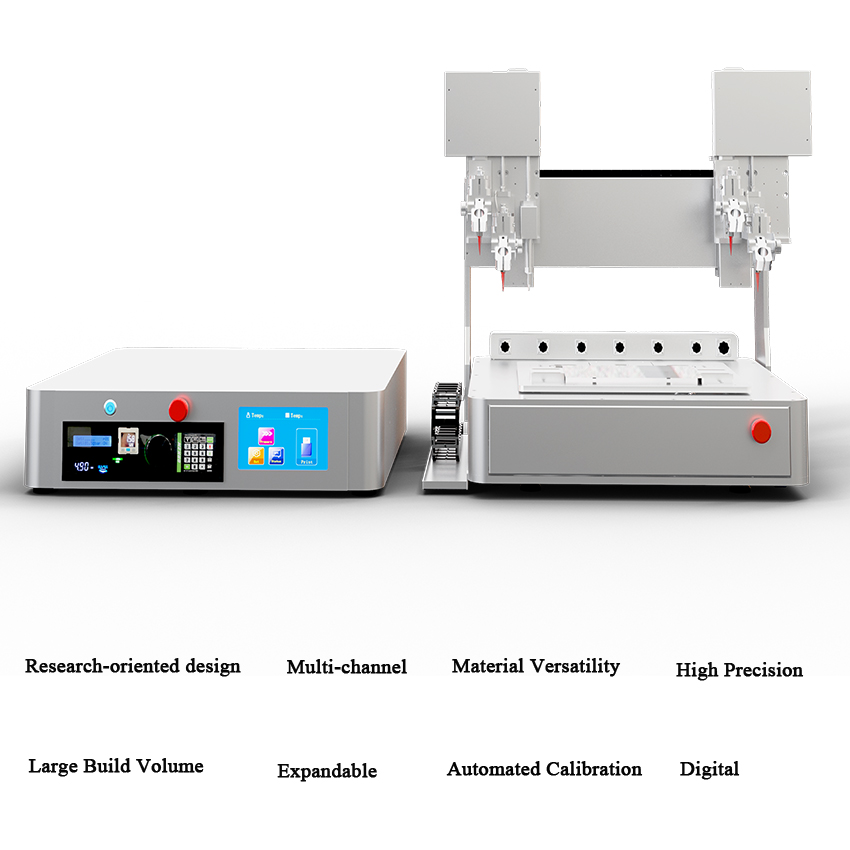

AutoBio Series Direct Ink Writing (DIW) 3D Printer

The AutoBio Series is a line of Direct Ink Writing (DIW) 3D printing systems independently developed by Soongon Technology (YuanYi Intelligence).

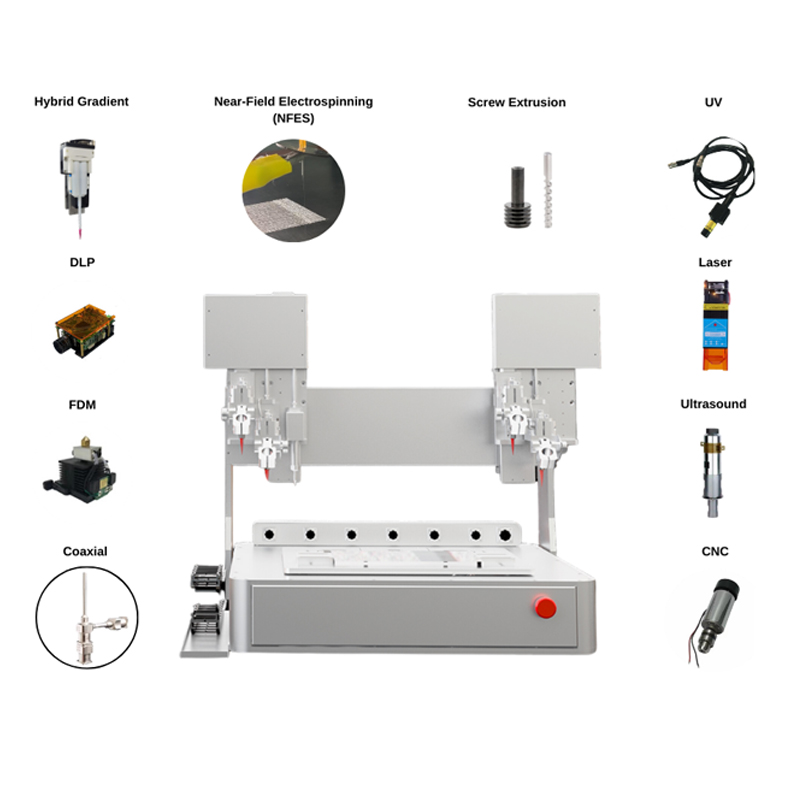

This series currently includes several configuration models—Standard, Professional, and Flagship—designed to meet different levels of research and application requirements.

The system supports a wide range of printable materials, including pastes, liquids, suspensions, and melts, such as silicone, hydrogels, gelatin, hydroxyapatite, drug-loaded cell suspensions, and other solution-, suspension-, or melt-based formulations.

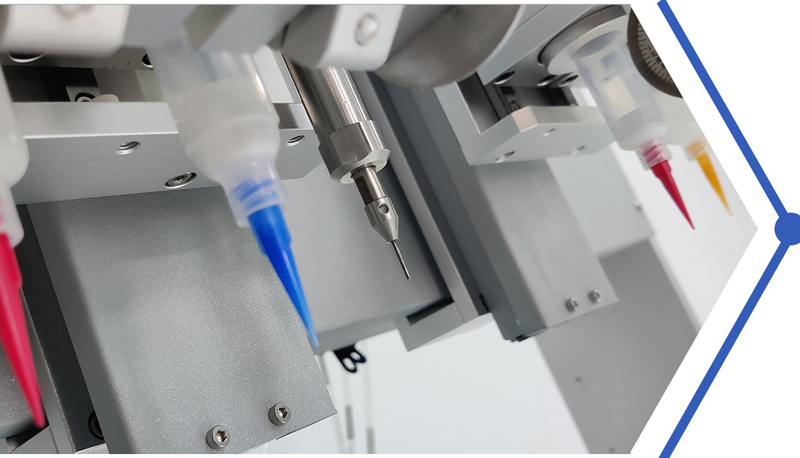

It is equipped with multiple interchangeable printing modules and functional accessories, allowing users to flexibly combine materials and modules to develop diverse printing strategies.

Through various combinations of material systems and printing modules, the AutoBio Series enables dozens of different printing process modes, covering a broad spectrum of research fields—such as personalized drug dosage fabrication, novel pharmaceutical formulation development, ceramic and advanced material studies, biomedical and cosmetic reconstruction, biomimetic tissue and organ modeling, tissue engineering scaffolds, cell culture research, and new material testing.

Why choose AutoBio?

01 The system is designed for research-oriented applications, providing comprehensive experimental data support.

It records and controls a wide range of parameters, including applied pressure, curing temperature, platform temperature, three-dimensional model data, nozzle diameter, reservoir diameter, and material viscosity, among others.

These parameters allow for precise process monitoring and reproducibility in scientific research.

The printer offers broad material compatibility and simple slurry formulation, enabling researchers to conveniently adjust the composition and ratio of materials during experiments.

Such flexibility makes the system particularly suitable for material development, process optimization, and performance evaluation in laboratory-based 3D printing research.

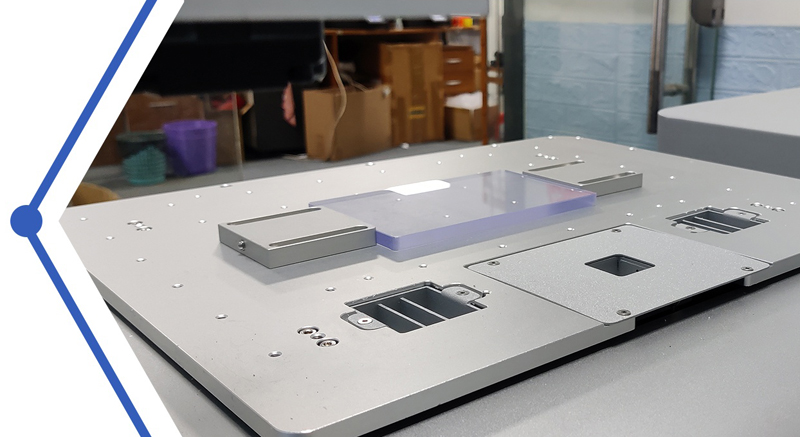

02 The system features a large build volume, providing a spacious working area for experimental fabrication.

The flagship model offers a maximum printing size of 300 × 200 × 100 mm, which accommodates the requirements of large-scale sample fabrication and batch printing for material research and testing applications.

03 The system offers material versatility and supports a variety of auxiliary modules and functionalities, including high-temperature and low-temperature printheads, high-temperature and low-temperature build platforms, UV-curing modules, coaxial extrusion modules, and electrospinning units.

These capabilities provide multiple processing environments, enabling the printing of different materials under their respective optimal conditions and fulfilling the requirements of diverse material research applications.

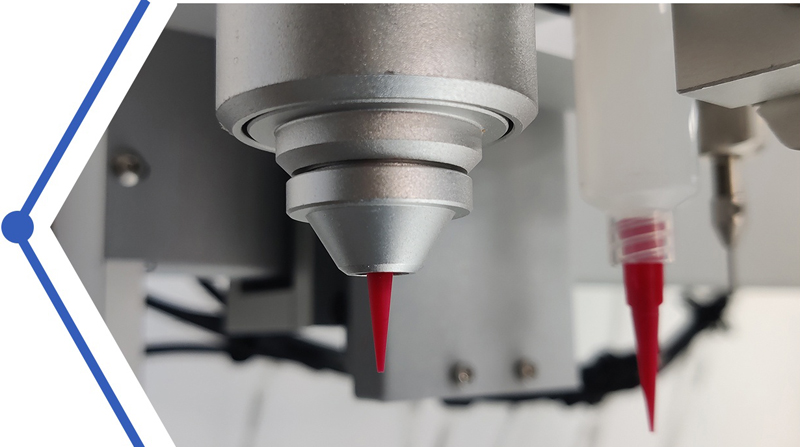

04 The system provides high printing precision, featuring a nozzle diameter of 0.1 mm, pressure control accuracy of ±0.2 kPa, mass error within ±3%, and mechanical positioning accuracy of ±10 μm.

These specifications ensure the system can meet the requirements of high-precision fabrication for experimental research.

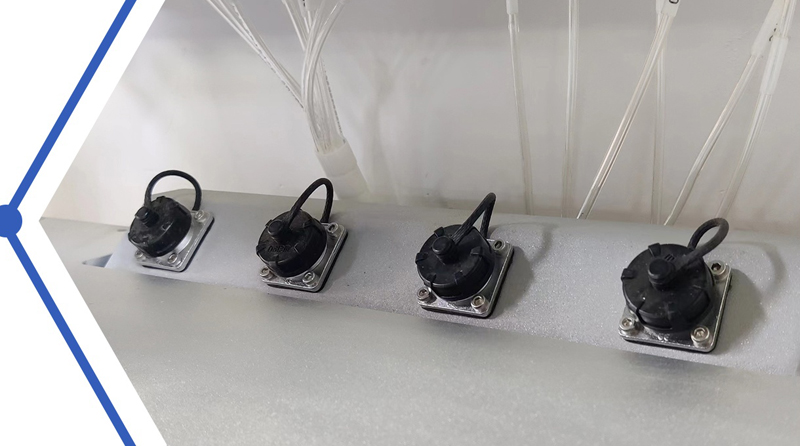

05 The system supports multi-channel printing, with 1 to 4 printheads configurable according to experimental requirements.

Through coordinated operation of multiple channels, the printer enables a variety of fabrication modes, including single-channel printing, multi-channel printing, combined-material printing, and replicated printing.

This flexibility allows for the concurrent processing of multiple materials and the implementation of diverse printing strategies.

06 The system is designed for upgradeability and expansion, featuring a redundant architecture and reserved expansion docks.

This design allows for the real-time addition of functionalities in response to newly identified experimental requirements.

Supported Materials

Liquid Crystal Elastomers (LCE) Polycaprolactone (PCL) PLGA

Alumina (Al₂O₃) Silica (SiO₂) Zirconia (ZrO₂)

Hydroxyapatite (HA) Magnesium aluminosilicate Tricalcium phosphate (TCP)

Zirconium nitride-silicon nitride (ZrSiN) Aluminum nitride (AlN) Hydrogels

Bone cement Low-temperature metals PDMS

Other polymeric or inorganic non-metallic materials that can be formulated as paste-like or meltable paste formulations.

Case studies of customized functionalities

Electrospinning, near-field direct writing, high-temperature melt spinning, high-temperature melt near-field writing

Coaxial modules: single-axis, 2-axis, 3-axis, and 4-axis coaxial printing

Rotational modules: standard, high-temperature, and low-temperature

Mixing modules: dual-component (AB) mixing, online mixing, active mixing, static mixing, and gradient mixing

Curing modules: ultraviolet (UV), infrared (IR), blue light, green light, laser-tracking curing, and ultrasonic curing

Advanced functionalities: variable nozzle diameter, suspended printing, CNC and drill modules, secondary motion platforms, vacuum platforms, coating and powder spreading platforms, multifunctional expansion platforms, and five-axis platforms

Biological sample platforms: well plate printing (96-well), petri dish printing

Temperature-controlled platforms: high-temperature platforms up to 100 °C, custom high-temperature platforms, cooling platforms, low-temperature platforms down to –10 °C, and dual heating/cooling platforms

Temperature-controlled printheads: cooling, low-temperature, –10 °C, dual heating/cooling, high-temperature up to 300 °C, high-temperature particle and powder extrusion printheads

Extrusion modules: screw extrusion, low- and high-temperature screw extrusion, plunger/piston extrusion

Inkjet and deposition modules: piezoelectric inkjet, piezoelectric adhesive, aerosol printing

Other modules: Joule heating, magnetic-field activation, explosion-proof design, vacuum design

The system also supports multi-modal integration of various 3D printing techniques, including DLP, SLS, FDM, and binder jetting (BJ).

For additional custom multi-modal integration or functional module requirements, please contact us for further consultation.

Customer Application Cases

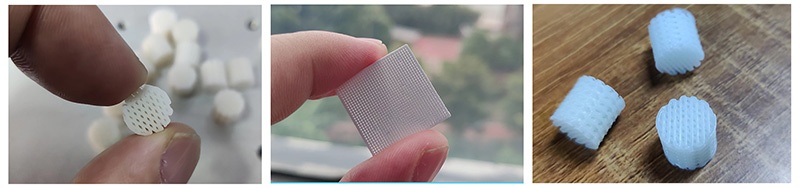

Case 1: Novel Drug Formulation Development

Using our multi-channel pharmaceutical 3D printer, precise control over drug composition and structure can be achieved. This allows accurate regulation of drug release time, speed, spatial location, and dosage, ultimately enabling precise adjustment of plasma drug concentration, improving efficacy while reducing side effects.

Case 2: Dosage-Specific Drug Printing

Our drug 3D printer can reshape commercially available drug powders based on computer-designed digital models, allowing precise control of individual dosage content. This addresses limitations of traditional methods, such as poor accuracy and uniformity, contamination risk, low compliance, and inability to mark dosages.

Case 3: Personalized Cosmetic Implant Design

Using our bioprinter with low-temperature printheads, low-temperature platforms, high-temperature printheads, and UV-curing modules, materials such as hydrogels and biodegradable implants (e.g., PCL + calcium phosphate) can be 3D-printed according to personalized requirements, reducing secondary injury and enhancing cosmetic outcomes.

Case 4: Orthopedic Ceramic Implants

With our ceramic 3D printer and high-precision ±1 kPa constant-pressure control, hydroxyapatite, zirconia, alumina, and other ceramic materials can be precisely fabricated according to digital parameters. This enables the design of personalized orthopedic implants and supports ceramic material research, providing detailed digital evidence for scientific studies.

Case 5: Composite Ceramic Sensors

Our ceramic 3D printer can fabricate composite structures combining piezoelectric ceramics and polymers, producing porous structures that enhance ceramic toughness. Multi-channel design allows printing different materials and ratios, enabling research and production of piezoelectric ceramic composite sensors.

Case 6: Gradient Ceramics

Using the online mixing module, two or more ceramic materials can be mixed in a graded manner during printing, achieving multi-component gradient ceramics. The module supports dynamic adjustment of material ratios. Combined with ±1 kPa high-precision constant-pressure control and ±10 μm mechanical positioning accuracy, this ensures precise and stable fabrication of complex gradient structures, offering an efficient and accurate solution for gradient material research.

Case 7: Flexible Electronic Tattoos

The AutoBio multi-channel ink direct-writing printer can layer conductive, insulating, and skin-friendly materials to fabricate flexible circuits and sensors for physiological monitoring and electrical stimulation to accelerate wound healing. ±1 kPa constant-pressure control and ±10 μm positioning accuracy ensure stable line width and reliable conductivity.

Case 8: 4D Printing of Liquid Crystal Elastomers (LCEs)

Using the AutoBio DIW printer with high-temperature and UV-curing modules, LCE materials can be printed under temperature, light, or magnetic field stimuli, imparting specific optical or mechanical properties. Applications include soft robots with autonomous deformation and motion, as well as smart wearable devices.