AutoBio Series Bioprinter

Independently developed research-grade 3D printing equipment, supporting multi-modal, multi-functional expansion and customization.

About the AutoBio Series

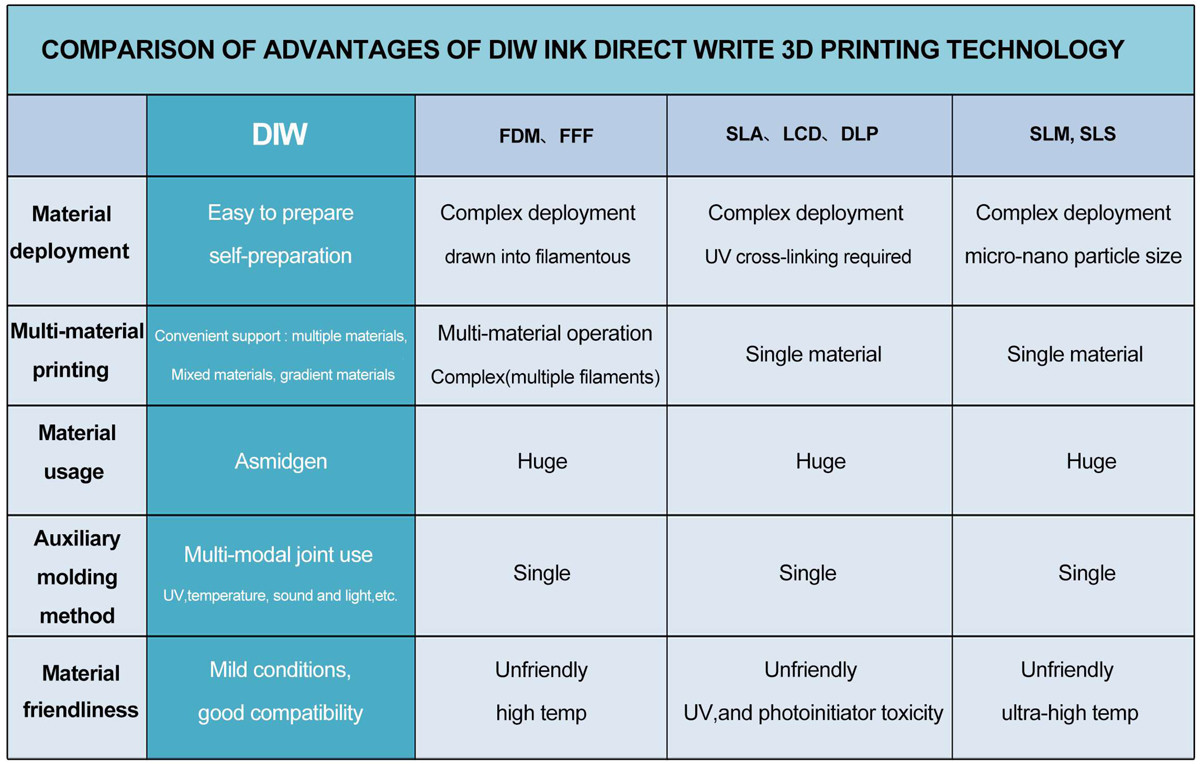

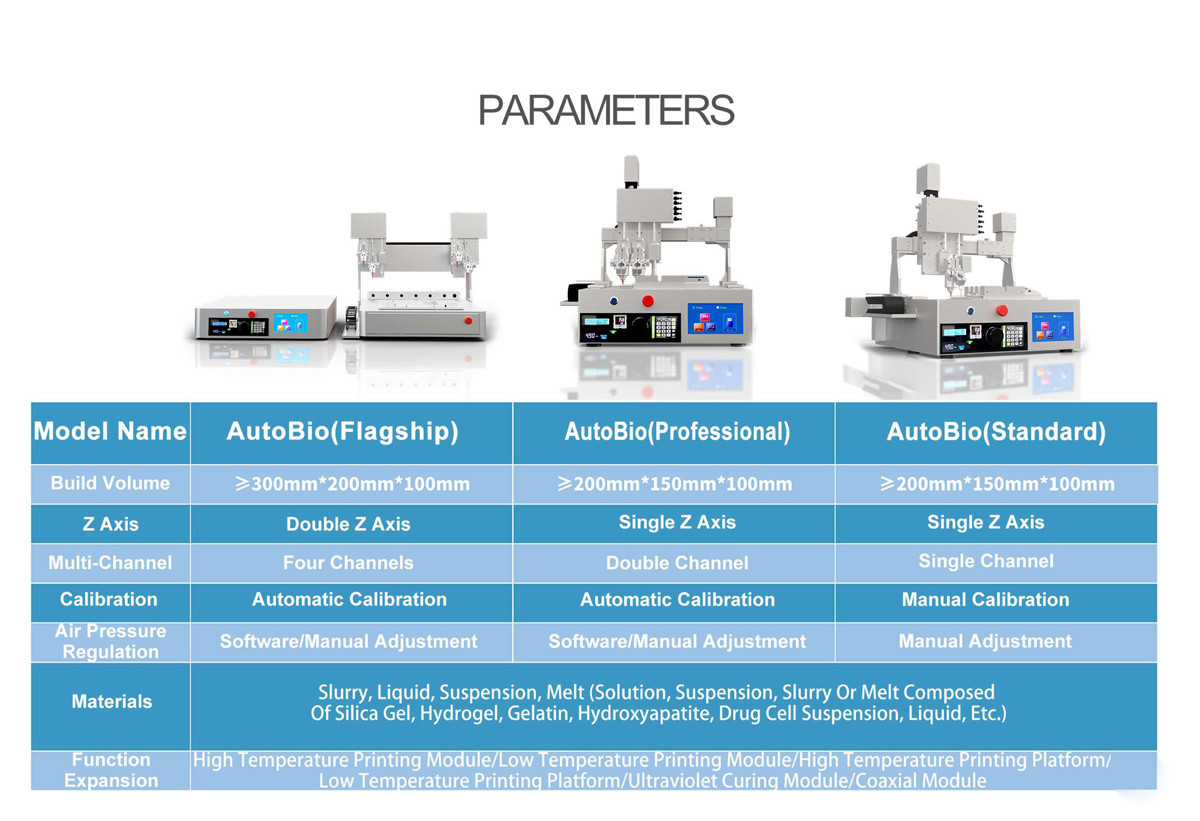

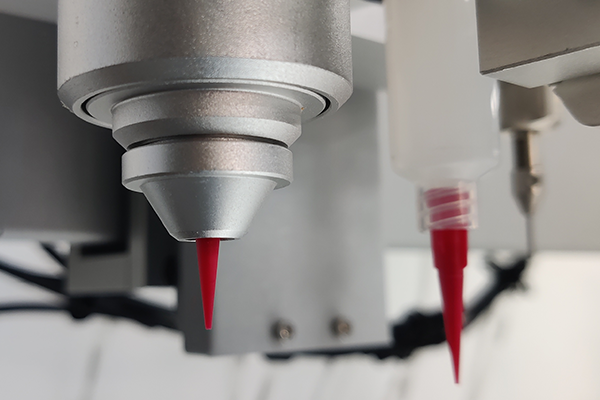

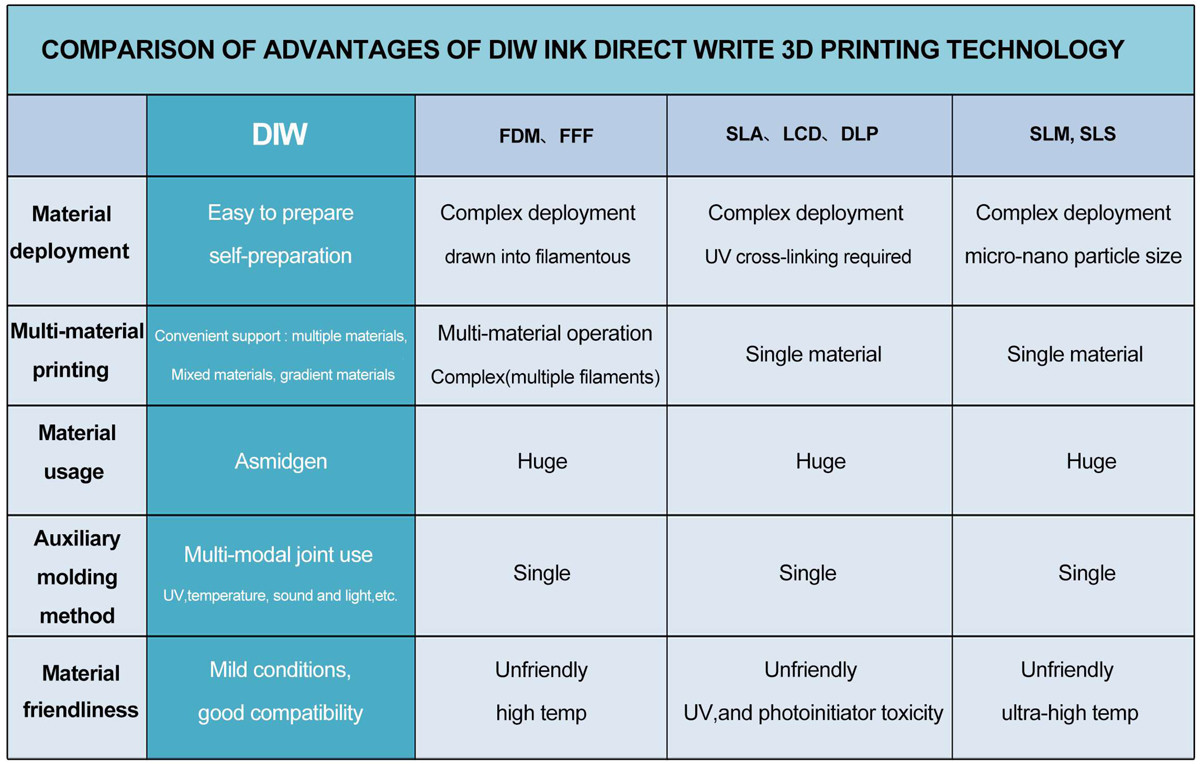

The AutoBio Series DIW (Direct Ink Writing) bioprinters are research-grade 3D printing devices independently developed by Soongon Technology. The series includes multiple configurations, such as Standard, Professional, and Flagship versions, supporting multi-modal, multi-functional expansion and customization.

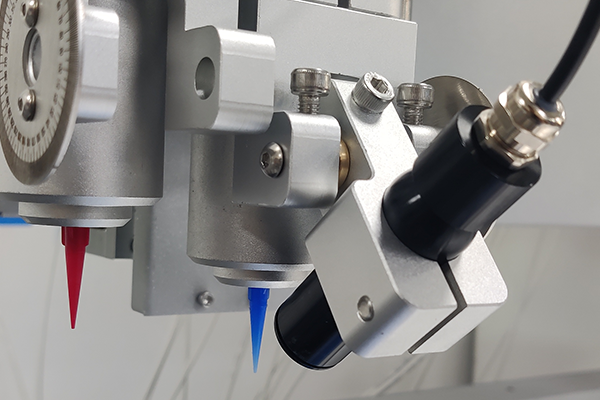

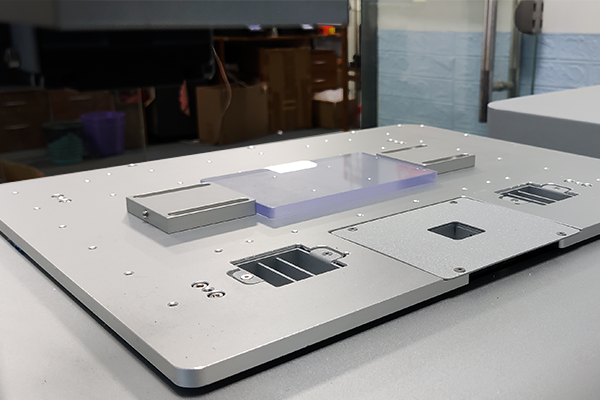

Featuring an independent dual Z-axis design, docking station design, and non-contact automatic calibration, the printers are compatible with a variety of printing platforms and offer multiple build volumes. They meet the diverse needs of research for multi-parameter control, digitalization, high precision, compact size, and expandability.

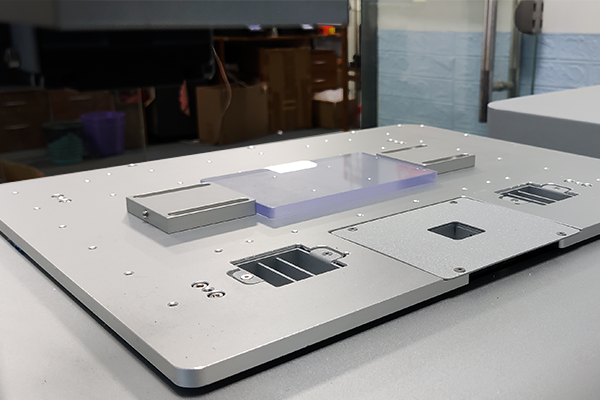

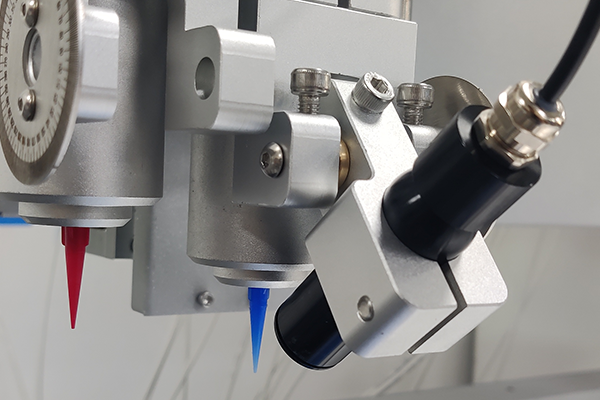

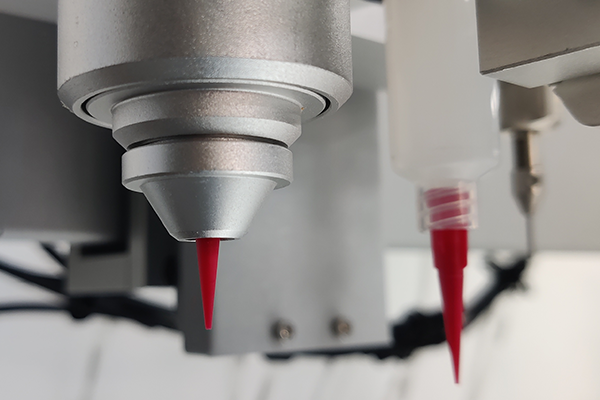

The series comes with multiple functional printing modules, allowing combinations of different materials and modules to address diverse research requirements. The equipment supports expandable modules such as high-temperature nozzles/platforms, UV curing modules, low-temperature nozzles/platforms, near-field direct writing/electrospinning modules, rotary-axis printing, and online mixing.

It is compatible with a wide range of materials, including suspensions, silicones, hydrogels, gelatin, hydroxyapatite, drugs, and cells, making it suitable for applications in biomedical research, tissue engineering, food, pharmaceuticals, and advanced polymer materials.

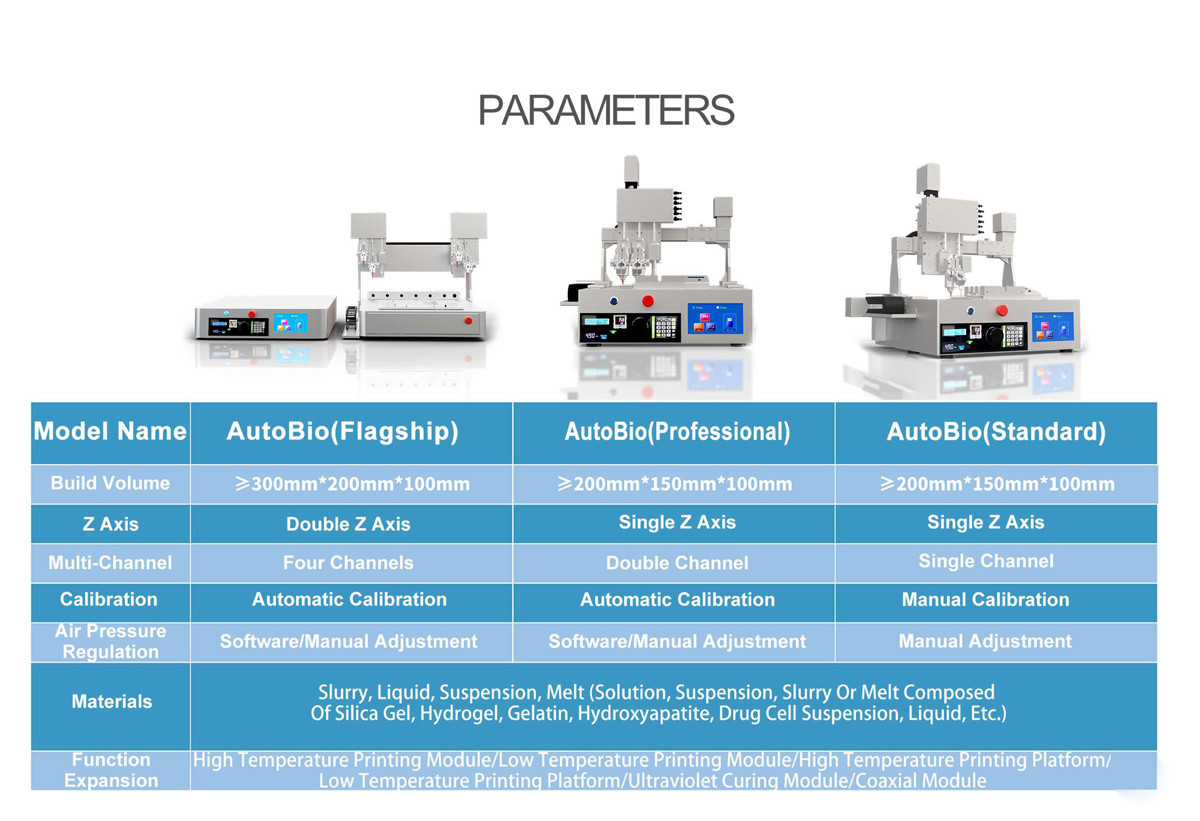

AutoBio Series Key Parameters

Core Product Advantages

1.Research-Oriented Design: Provides a comprehensive set of data including pressure values, curing temperature, platform temperature, 3D model data, nozzle diameter, syringe/barrel diameter, and material viscosity, supporting a wide range of research needs. The printer supports a broad range of materials, with easy slurry preparation that allows real-time adjustment of material composition during experiments, fully meeting the requirements for material research and printing tests.

2.Large Build Volume: Offering an expansive workspace, the Flagship version supports a maximum build size of 300 × 200 × 100 mm, meeting the needs for large-scale and batch printing in various material research and testing.

3.Material Versatility: Supports a variety of auxiliary printing modules and functions, including high-temperature and low-temperature printheads, high- and low-temperature platforms, UV curing modules, coaxial modules, and electrospinning. This provides diverse printing environments to meet the specific forming requirements of different materials.

4.High Precision: Features a nozzle diameter of 0.1 mm, pressure resolution of 1 kPa, mass accuracy of ±3%, and mechanical positioning accuracy of ±10 μm, meeting the requirements for high-precision printing.